No products in the cart.

Veneer

Contact

Thin sheets of wood used for decorative purposes and in the production of plywood. Our veneers are sourced from high-quality timber, ensuring durability and a beautiful natural grain.

Category: Wood

Factory scale

Our veneer manufacturing facility spans thousands of square meters and is equipped with state-of-the-art machinery and a closed-loop production line. The expansive space and efficient design ensure we meet all production and quality standards.

eucalyptus log yard

Our eucalyptus log yard marks the beginning of our veneer production process. High-quality logs are carefully selected from sustainable forests and transported to our facility for processing. Here, they are meticulously arranged and prepared for the production line, where they are transformed into beautiful veneers that meet the diverse needs of our customers

modern industrial saw

“The image showcases eucalyptus logs being precisely cut to the desired dimensions. The smooth and powerful saw cuts through the wood with ease, creating uniform logs ready for the peeling process. The high precision of this step is crucial for ensuring the quality of the final veneer product.”

Debarking

The image depicts a worker operating a peeling machine to gently remove the rough bark from a eucalyptus log. This process not only removes the outer layer but also reveals the beautiful natural grain patterns of the wood. The veneers produced from these treated logs will add a unique touch to any space.

Veneering

The image shows peeled eucalyptus logs being conveyed on a conveyor belt at a steady pace. They are about to enter the next critical stage: the peeling process, where they will be transformed into thin veneers that serve as the primary raw material for manufacturing furniture and other wood products

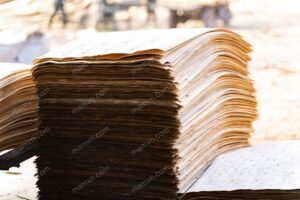

freshly veneers collecting

The image shows freshly peeled veneers being neatly collected and stacked onto carts. After drying, they will be used as the primary material for producing high-quality wood products such as furniture, flooring, and plywood

drying

The image shows carts loaded with fresh veneers being transported to our expansive drying yard. Here, the veneers are systematically stacked on elevated racks and exposed to sunlight. The drying process is carefully controlled to ensure the quality and durability of the final product

Collecting dried veneers

The dried veneers are handled with utmost care to prevent scratches or warping. Each veneer is carefully stacked to maintain its pristine condition before being stored

Quality inspection of veneers

The image shows a worker using a moisture meter to test the moisture content of eucalyptus veneers. Rigorous moisture control is essential for ensuring the quality and durability of our products. Only veneers that meet our standards are packaged and delivered to customers

Reviews

There are no reviews yet.